Archibus SaaS / Maintenance / Background Data - Maintenance

Develop Maintenance-Related Background Data

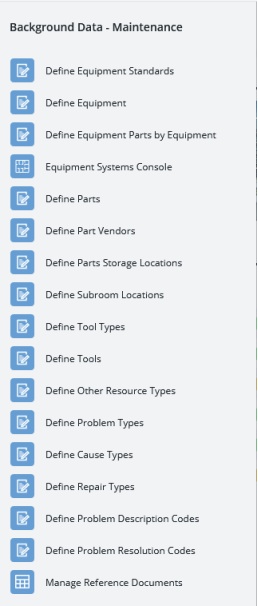

Develop the following validating data used by the Maintenance module. If you are working with the Assets module, you likely have already developed your equipment inventory.

Equipment

Use the following to establish your equipment inventory. For information on representing your equipment in floor plans, see Draw Equipment.

| Task | Description | Help Topic |

|---|---|---|

| Define Equipment Standards | Define the standards that categorize your equipment | |

| Define Equipment | Develop your equipment inventory by entering. key information for the equipment. | |

| Equipment System Console | Use this task to make and understand equipment relationships. You can also develop your equipment with this task. | Equipment Systems Console (Overview) |

Parts and their locations

Optionally, you can develop a parts inventory. This enables you to track the costs of parts and avoid shortages.

You may wish to add this level of detail once you have implemented other aspects of the module. Once you enter the initial inventory, you maintain it with the Parts Inventory process.

Note: If you are tracking parts for your site's vehicles, enter the vehicles in the Equipment table and the vehicle parts int the Storage Locations table. Doing so enables you to manage these vehicles as equipment for preventive maintenance.

| Task | Description | Help Topic |

|---|---|---|

| Define Parts | Define parts so that you can track and manage them in the application. | Define Parts |

| Define Equipment Parts by Equipment | Use this task to associate equipment and equipment parts. | Define Equipment Parts by Equipment |

| Define Parts Vendors | Associate parts with vendors so that you can generate purchase orders for these parts. | Maintaining a List of Part Vendors |

| View Parts by Vendor | Generate this report to review key information for parts by vendor. For example, you can see whether the part is understocked ,and the average cost. From this report, you can run the Update Calculations action to ensure that the data is up-to-date. | |

| Define Parts Storage Locations | Parts are associated with a storage location to help you better track and mange your parts. Storage locations can be warehouses, storage closets, mobile carts, or even vehicles. If you do not want to track parts by location, all parts are assigned to the 'Main' (default) storage location. | Define Part Storage Locations |

| Define Subroom Locations | If you define parts storage locations to the room level, you can assign the part an aisle, cabinet, shelf, and bin number. his form includes the fields for aisle / shelf / cabinet / bin. | Define Subroom Locations task |

Tools and other resources

See the following topics for developing tools and other resource types used at your site:

| Task | Description | Help Topic |

|---|---|---|

|

Define Tool Types Define Tools |

Define the types of tools and exact tools used at your site. | |

| Equipment Systems Console | When supervisors add an estimate for a work request, they can estimate costs for labor, parts and tools. These estimates contribute to the costs summaries shown in reports. If you want to track other types of costs, such as costs for transportation, or permits, you can add Other Resource Types that provide ways of categorizing these additional costs. | Define Other Resource Types |

Work classifications

Your site may wish to analyze your maintenance costs and histories in terms of categories. Use the following tables to establish classifications for problems and their resolution.

| Task | Description |

|---|---|

| Problem Types |

Use this table to define frequently occurring problems, such as installation, leaks, and safety. The Problem Types table is used by other applications, including Hazard Abatement and offers the unlimited-tier hierarchy feature so that you can optionally prefix the problem types to show related items. For example, the sample data uses the parent |

| Cause Types | The Cause Types table defines typical causes of maintenance and repair problems, such as accident and vandalism. |

| Repair Types |

The Repair Types defines common resolutions to problems, such as cleaning, replacing, and moving. |

| Problem Description Codes | Use the Problem Description Codes table to enter a list of common problems by completing the Problem Desc. Code field with a unique value and the Problem Description memo field with a memo describing this problem. When users report problems, they can automatically complete the work request’s Problem Description field with a descriptive memo from the memos stored in this table. This is useful for minimizing the typing required when requesting work, and for standardizing the way work problems are described. |

| Problem Resolution Codes | Use the Problem Resolution Codes table to enter a list of common resolutions by completing the Problem Resolution Code field with a unique key and the Problem Resolution memo field with a memo describing this solution. When craftspersons record details about the job, they can use these values to automatically complete a work request’s Craftsperson Notes field with a descriptive memo. |

Manage Reference Documents

Reference documents are documents stored in the Assigned Documents table that are associated with an equipment or furniture standard, a building use, property type, PM procedure, work request problem type, action item, action type, or project type. You can also associate a document with a URL, or can mange documents from the Documents tab to more easily locate a document.