Archibus SaaS / Maintenance / Workflow

Maintenance / Corrective Maintenance / Business Manager

Maintenance / Preventive Maintenance / Maintenance Manager

Maintenance Checklists: Overview

You create maintenance checklists using the extended questionnaire feature to develop a list of questions that the field personnel should answer as part of their work on a maintenance job. The checklists can include a variety of response options, such as multiple choice, yes/no, free-form text, attached photos or documents, counts, look-ups, and measurements, as well as provide follow-up questions and actions based on initial response.

You can access checklists from these tools:

-

OnSite mobile app

-

Maintenance mobile app

-

Maintenance Console

Maintenance checklists have several uses in corrective and preventive maintenance:

- Maintenance managers can ensure that work is properly completed by outlining the steps for maintenance work in the form of a checklist and associating the checklist with the work request. The craftsperson can then refer to the checklist when executing the work. They can check off each step as they complete it, respond to a series of questions to inspect an item, enter measurements, and so on. In the field, craftspersons complete checklists using the Maintenance mobile app or by working with the Maintenance Console on a tablet or laptop.

- To document that equipment is maintained properly, craftspersons often must complete very lengthy questionnaires from the equipment manufacturer to verify that all proper steps were taken. Setting up these questions as checklists attached to the work order enables the craftsperson to complete the questions at the time they service the equipment. The responses are saved to the database, thereby providing documentation that all steps were followed.

- Maintenance work often requires multiple permits. For example, for a job on the roof using an open flame might require a working at heights permit and a hot works permit. Obtaining these permits can managed through checklists such that you create a checklist for each permitting step.

- Maintenance checklists can track light compliance reporting needs; for example, you might have a series of steps that you need to take in order to inspect an item for safety. If you wish a more comprehensive compliance system that tracks programs, regulations, and requirements, you can work with the Compliance application and its compliance surveys.

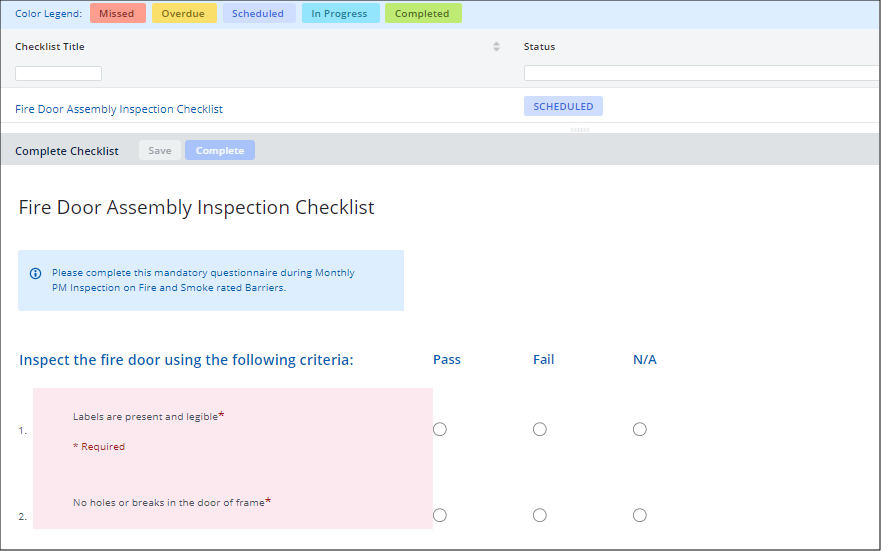

- Safety inspections require that a craftsperson work through a series of steps and record their completion. For example, a maintenance technician inspecting fire doors in a hospital can access the fire door checklist using the Maintenance mobile app and work through the checklist to inspect the door. and record my answers in the system.

Field personnel inspecting items or working through procedures use the Maintenance mobile app, OnSite, or the Maintenance Console to access checklists, enter their responses, and save the data to the system, thereby creating a record of the work performed.

The Archibus Extended Questionnaire System

Maintenance checklists use the underlying extended questionnaire technology to hold questions and user responses. Review the Concept: Questionnaire Tables topic for an understanding of how the extended questionnaire system stores questions and responses.

The extended questionnaire technology is also used by the Compliance application's survey features. For users defining questionnaires, Archibus provides two views:

- Define Maintenance Checklists (ab-pm-checklist.axvw)

- Define Compliance Questionnaires (ab-comp-checklist.axvw)

The two views operate very similarly, but there are some differences. For features that operate the same in both views, the online help provides one topic. In this case, the topic uses the generic "questionnaire" terminology rather than "checklist" or "compliance survey." For features that do not share the same user interface, the online help provides separate topics. Consult the Navigator paths at the top of a topic to see if the topic applies to both Compliance and Maintenance.

Link Checklists to Maintenance Workflow Using SLAs (Corrective and Preventive Maintenance)

Maintenance SLAs are the vehicle through which checklists are linked to work requests; you assign one or more checklists to the Issued status of an SLA.

Since you can create SLAs based on location, equipment type, problem type, and so on; you can associate a different checklist with each SLA to create checklists specific to these various components. For example, you might create a generic checklist for inspecting the safety and cleanliness of a particular type of equipment and associate this checklist with the SLA for this equipment standard. Suppose there is a unique situation for a particular item of this standard (for example it has a rebuilt engine) and you want to inspect additional elements. You could copy the checklist for the equipment standard, modify it accordingly for this particular equipment item, and then assign it to an SLA for this particular equipment item.

Because you can associate checklists with the flexible SLA system, you will find that the checklist system can accommodate a variety of situations. Moreover, the extended questionnaire system has many features to quickly create new checklists based on the checklists you have already defined so that you will be able to quickly generate checklists for these situations.

Link Checklists to Maintenance Workflow Using PM Steps (Preventive Maintenance Only)

For your PM work, you can associate checklists with SLAs as described above. Additionally, you can directly connect a checklist to a step of a PM procedure, omitting the need for an SLA. This makes checklists available in situations where you do not define SLAs for PM procedures.

See Methods for Adding Checklists to PM Workflow.

Working with Multiple Tools

The Maintenance mobile app, OnSite, and the Maintenance Console provide access to maintenance checklists. When craftspersons and supervisors sign in and access their work requests, they can access the specific checklists for each work request.

It is possible to switch between tools. For example, you might complete part of the checklist in the field using the mobile app, sync to upload your responses to the server, and then access the In Progress checklist using the Maintenance Console once you return to the office. Likewise, you could start in Maintenance Console, save your changes, and then sync in mobile to upload the In Progress checklist to mobile.

Concepts

- Comparing Maintenance Checklists and Compliance Surveys

- Methods for Adding Checklists to PM Workflow

- Using Compliance Questionnaires with Maintenance Workflow

- Extended Questionnaires: Events and Status

- Tables for the Extended Questionnaire System

General Procedure

- Use the Define Maintenance Checklists task to create checklists that craftspersons can use in the field.

- Connect checklists to the maintenance workflow with these methods:

- For corrective and preventive maintenance, assign one or more checklists to an SLA's Issued status.

- For preventive maintenance, connect a checklist to a step of a PM procedure.

- Create corrective work orders and generate PM work orders in the standard manner.

- Maintenance workers perform their work, and access the checklists associated with the work. There are a few possibilities:

- Craftspersons in the field use the OnSite mobile app to complete checklists.

- Craftspersons in the field use the Maintenance mobile app to complete the checklists and then upload their answers.

- Craftspersons complete checklists using the Maintenance Console. They can do so using a tablet or laptop while in the field, or, enter the responses after returning from the field.

- On behalf of craftspersons, supervisors complete checklists using the Maintenance Console.

- Optional Supervisors verify completed checklists and, if necessary, send checklists back to craftspersons for updating. (This step is available only from the Maintenance Console.)

- Managers review all checklist responses using the Maintenance Survey Report.