Technologies / Innovative Solutions / Integrations - BMS

Integrating with Clockworks BMS

Maintenance managers can take advantage of the Internet of Things (IoT) and Building Management Systems (BMS) technology to report on real-time asset conditions and alert the maintenance team to problems before they become critical. For example, maintenance managers can:

-

see, through an associated BMS, both real-time and historical diagnostic data for their assets; and use this data to monitor how assets are performing, and whether there are any concerns or risks

-

have high-value assets self-report and create work orders when a measured attribute, such as temperature or vibration, goes out of bounds;. They can have someone check the asset before it fails.

To meet these needs, Archibus integrates with a BMS system from Clockwork Analytics. Clockworks Analytics has researched the typical issues that result in equipment downtime and expenditure, and has developed a focused set of analyses for diagnosing equipment. Diagnostic data can include temperature, vibration, or any other applicable measured property.

Integrating these diagnostics into the Archibus maintenance workflow enables you to implement a proactive, condition-based approach to maintenance that ensures asset health. Regularly importing and reviewing equipment diagnostics provides a wealth of information about your facility equipment. Moreover, high-priority diagnostics can automatically generate work requests so that technicians can investigate and address problems before assets fail.

While responding to any equipment-related work request -- even those not auto-generated from a diagnostic -- maintenance staff can consult the asset's diagnostic history so that they can perform additional checks while on site.

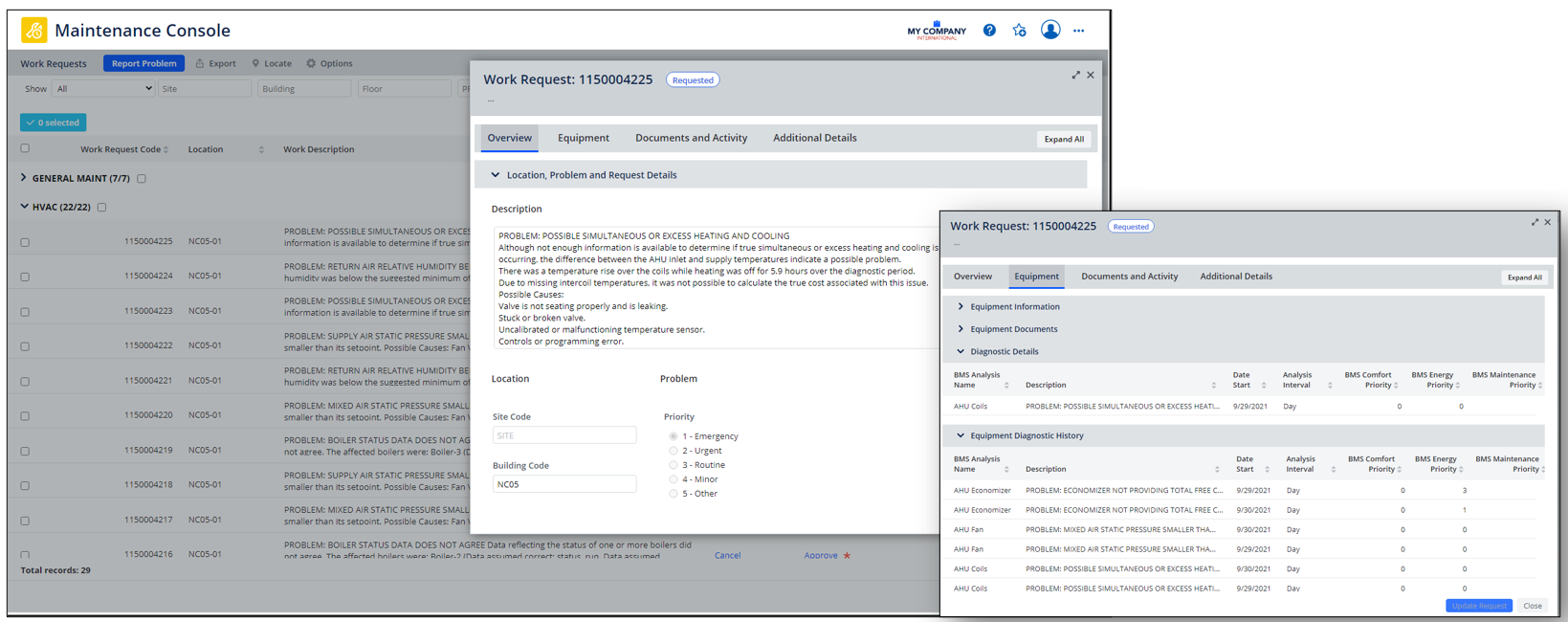

When working with work requests in the Maintenance Console, you will find that diagnostic information is integrated into such areas as filters, the work request's Problem Description, and the Equipment tab of the Work Request form.

Help Topics