Getting Results with Archibus

Preventive Maintenance

In order to prevent deterioration and breakdown of the facility, organizations need to monitor the maintenance of buildings and assets and prevent problems before they happen. Preventing a piece of production equipment from malfunctioning by periodically changing its air filters is well worth the time and effort of planning and executing this task.

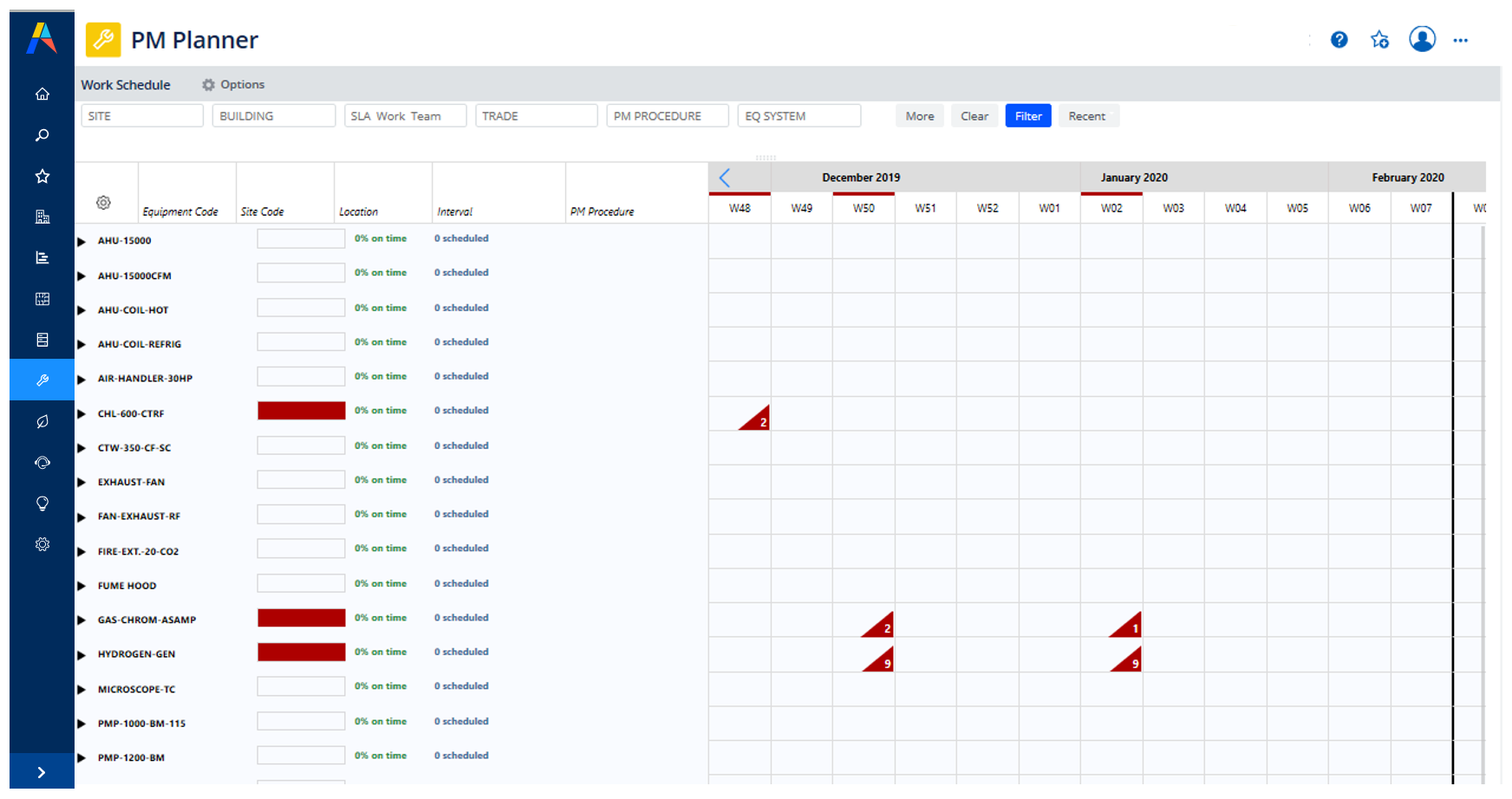

The Preventive Maintenance application provides tools and reports that help you establish and manage a comprehensive preventive maintenance program for your time-based and meter-based, regularly occurring maintenance work. Use the application to define tasks such as inspection, calibration, adjustment, cleaning, lubrication, and parts replacement and schedule these jobs at intervals necessary to prevent breakdown and maintain proper operation Once you define the maintenance schedule, you can instruct the system to automatically generate work orders for executing these defined tasks.

By automating preventive maintenance, organizations minimize the risk that critical maintenance is missed or that errors occur. In addition, automation ensures efficient and timely work order execution, effective balancing of schedules and resources, and information tracking for planning and reporting purposes.

|

Preventive Maintenance |

|

|---|---|

|

Location |

Archibus non-SaaS

|

|

Business Result |

Prevention of deterioration and breakdown of equipment and facility. Improved preventive maintenance for all assets and locations, based on time intervals or meter reading intervals and based on defined procedures and steps. Improved efficiency in equipment operation with less downtime due to broken equipment. Improved safety and working environment for staff as equipment and facility is regularly serviced and remains in good working order. |

|

Used By |

Facilities Managers Maintenance Managers Service Desk Managers Supervisors Craftspersons Equipment Managers |

|

Reasons for Automating |

Provide a comprehensive and automated planned maintenance schedule with predefined resource (trade, part, and tool) assignments. Reduce operating costs by automatically generating work requests according to predefined schedules and service level agreements. Automate work order generation and craftsperson assignment to PM work. Automate the escalation of overdue PM work by developing service level agreements and matching these to work requests. Reduce operating costs by reducing equipment downtime. Reduce capital costs by lengthening equipment useful life. Increase efficiency by providing maintenance managers with an intuitive interface for creating and scheduling PM work. Provide a complete, web-based solution for managing all maintenance applications. Balance the workload for craftspersons who undertake PM jobs. Capture metrics on service provider workload and performance. |

|

Management Reports |

Summary Reports Maintenance Report Builder Maintenance Survey Report Search Work Requests Current Work & Planning Work Request Budgets and Costs Work Request Schedules and Costs Open Work Requests Overdue Work Requests Historical Work & Trends Completed Work Request Budgets and Costs Costs of Completed Work Requests Building Costs by Area and Occupancy Equipment Maintenance History Labor Analysis Historical Work Statistics Archived Work Requests Work Request Aging Dashboards Labor Analysis Dashboard Cost Analysis Dashboard Budget Analysis Dashboard |

| Operational Reports |

Summary Reports Maintenance Report Builder Maintenance Survey Report Search Work Requests Current Information Current Equipment, Labor, Parts Inventory, Tools reports Equipment Warranties and Service Contracts Equipment Parts Current Work & Planning Equipment Schedules Trade and Craftsperson Workload Trade and Craftsperson Availability Reserved Parts Physical Inventory Variance Tools and Tool Types Availability Status of Tools PM Schedules Overdue PM Schedules Statistics Locations of Work Requests Work Requests for Same Equipment or Location Historical Work & Trends Equipment Failure Analysis Equipment Replacement Analysis Craftsperson and Trade Performance Craftsperson Time Usage by Work Type Craftsperson Time Usage by Date and Time Tool Usage History Parts Usage History Historical Work Statistics Archived Work Requests and Resources |

|

Related Applications |

|

The following are typical users:

|

User |

Tasks |

|---|---|

| Maintenance Managers |

Define procedures and their required resources for common preventive maintenance tasks. Define maintenance checklists. Assign common procedures to specific locations and equipment and establish schedules for servicing these items and areas. Generate work orders and work requests based on the defined schedules. Forecast future work and resources by month or week. |

| Service Desk Managers | Define and manage service level agreements (SLAs) that govern the work that supervisors and craftspersons do on PM work orders, and for searching and re-assigning in-process PM work orders. |

| Supervisors |

Schedule the generated work by assigning craftspersons and tools to work orders. Evaluate craftsperson workload, availability, and efficiency. If they have the Maintenance mobile app, they can do this over their mobile device or smart phone. |

| Craftspersons |

Execute the work that is defined on the generated work orders, including maintenance checklists. After job completion, update the system with details about how the job was completed. If they have the Maintenance mobile app, they can do this over their mobile device or smart phone. |

| Equipment Managers | Analyze equipment maintenance and efficiency with the equipment analysis reports. |

| Facility Managers | Analyze maintenance costs and efficiency with the performance, forecast, and history reports. |

| Business Process Owners | Maintain facilities background data and validating maintenance background data. |