Archibus SaaS / Maintenance / Preventive Maintenance

Maintenance / Preventive Maintenance / Maintenance Manager

Assigning Procedures to Equipment and Locations

After defining your general preventive maintenance procedures, the next step is to assign these general procedures to specific equipment items and locations in your facility by running the Assign Procedures to Equipment or Location task (ab-pm-asgn-procs-to-eq-hk.axvw). For example, if you have defined a general procedure for changing a filter, you can assign this procedure to each equipment item whose filter must be changed.

You most likely will have multiple procedures for each item. For example, a conference room may need to be vacuumed daily, have its windows washed every three months, and be painted once a year. Thus, this room would have three maintenance procedures assigned to it.

If you wish, you can assign multiple procedures to multiple equipment items at one time. For example, you might want to select at one time all equipment items that have filters, and then assign the filter-changing procedure.

From the Locations tab, you can also select multiple locations for the procedure. The selection boxes include selections for the entire site, entire building, the entire floor, or for individual rooms. For procedures that affect all rooms, assign the procedure to all rooms by selecting the floor. For a group of special rooms that require a unique procedure, you can select the check boxes for the individual rooms.

Working with Equipment Systems

If you have organized your equipment into equipment systems, you can use the System tab to view equipment items in terms of their systems and make your procedure assignments from this tab. It is often helpful to know if a piece of equipment is a component in a larger system so that you can view and plan for system maintenance and component maintenance. For example:

- You may want to plan PM work for an entire system, not just all individual pieces of equipment that are components of that system. This allows for a more holistic approach to planning that increases efficiency and minimizes disruption. If there are exceptions, then independent component planning is also needed.

- If a system is scheduled to go offline, then maintenance work for its components can sometimes be deferred until the system goes offline. This allows for minimal interruption of the organization’s normal daily use of that equipment.

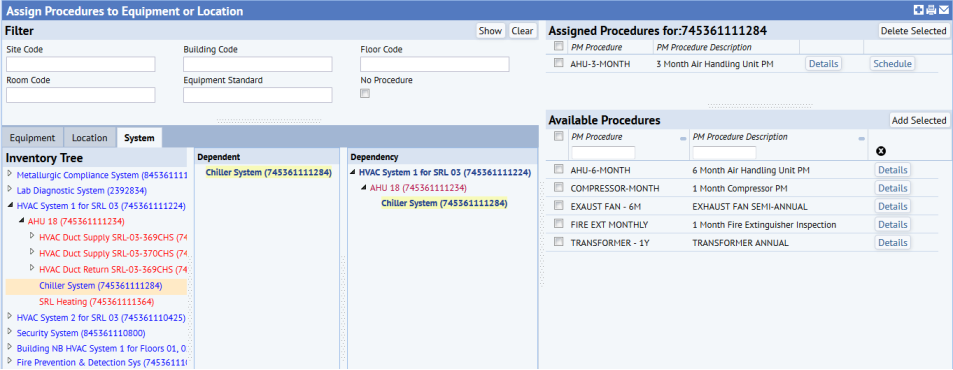

The System tab of the Assign Procedures to Equipment or Location task displays the Equipment System hierarchy tree, with each node on the tree representing one piece of equipment.

You assign procedures to the equipment items of a system, not the system as a whole. In other words, there is no difference between using the Equipment tab or System tab to assign a PM Procedure to a piece of equipment; the System tab simply organizes the list of equipment into the defined Equipment System hierarchy trees.

Select a node from any of the three panels and see that equipment item's assigned procedures in the right panel.

In the below image, the user has drilled down in the Inventory Tree to see the components of the HVAC System 1. The user then selected the Chiller System and can see its higher level items in the Dependency panel. With the Chiller System record selected, the user can choose a procedure from Available Procedures and assign it to the chiller system and use the Schedule button to set a schedule. If they want to perform other maintenance tasks on other components of HVAC System 1, they can easily see related components and set the same schedule for these items.

Reviewing Existing Assignments

- Load theAssign Procedures to Equipment or Location task. In the left pane you can toggle between a list of equipment, locations (buildings, floors, and rooms), and equipment systems in your facility, and in the right pane you will review procedures for these items.

- You may wish to first filter your list of items so that you can see related items, which will likely need the same procedure.

- You might want to apply the same procedure to all equipment or rooms located on the same floor or all equipment of the same standard.

- You may wish to view items to which procedures have not yet been assigned. For example, you might have new rooms or equipment to which you need to assign procedures. If you wish to list only items that do not have assigned procedures, choose the No Procedure option in the filter.

- You might want to review the component equipment of an equipment system, as described above. Note that you cannot assign the procedure to the entire equipment system; you must assign it to the individual components.

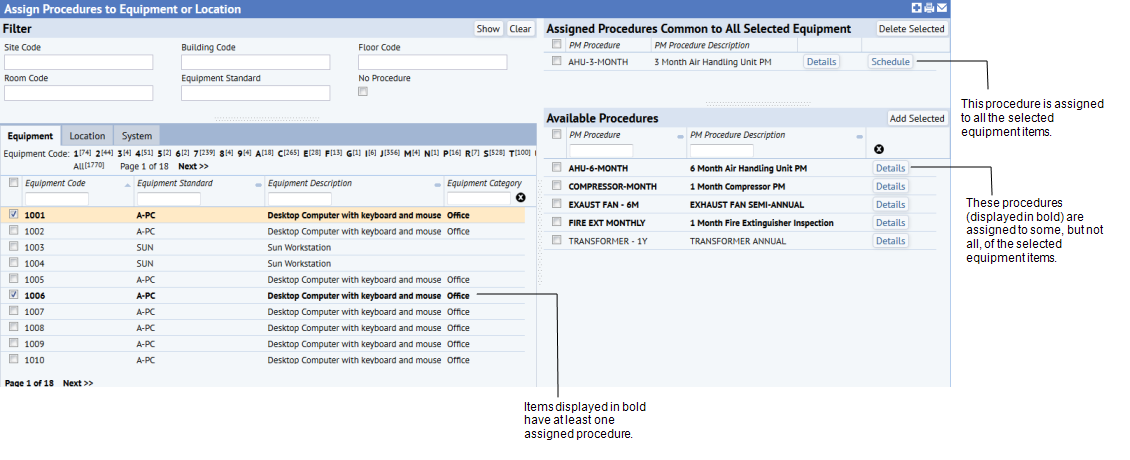

- The task displays the locations, equipment systems, or equipment items that match your filter. Note that any location. equipment system, or equipment item that has at least one assigned procedure appears in bold font.

- To review assignments for one item at a time, select the room, equipment system, or equipment item whose procedures you wish to review.

- In the top right frame, "Assigned Procedures for XX", the system lists the procedures assigned to this item.

- Use the Details button to review the details of the procedure.

- Use the Schedule button to review the schedule for executing this procedure on the equipment or location. You can edit the schedule if you wish. Be sure to save your changes with the window's Save button. For information on setting the schedule, see the Define PM Schedules task.

- When working with the Equipment and Locations panes, you can review assignments for multiple equipment items and locations at one time. Select a set of items by clicking on their check boxes; or, select all items by choosing the check box in the column header.

- In the top right frame, "Assigned Procedures Common to All Equipment/Locations," the system lists the procedures that are assigned to all selected items.

- You may have situations in which your selected equipment and locations that do not share the exact same set of procedures. In this case, the top frame will list the procedures common to the selected items, and the bottom right frame, "Available Procedures" will highlight in bold the procedures that are not assigned to all selected items. See the below image for an example.

Making New Assignments

- Load the Assign Procedures to Equipment or Location task, set a filter, and in the left pane you can toggle between a list of equipment, equipment systems, and locations in your facility.

- Note that any location or equipment item that has at least one assigned procedure appears in bold font.

- You may wish to view items to which procedures have not yet been assigned. For example, you might have new rooms or equipment to which you need to assign procedures. If you wish to list only items that do not have assigned procedures, choose the No Procedure option in the filter.

- From the Equipment or Location tabs, click on the check boxes to select a set of items to which you want to assign the same set of procedures. To select all equipment or locations displayed on the screen, choose the check box in the header. When working from the System panel, select equipment items using the Inventory Tree as described above.

- Select one or more procedures from the Available Procedures window and click Add Selected. If you wish, you can first review each procedure's details using the Details button.

- In the top frame, the system lists these procedures as being assigned to the selected items.

Deleting Procedure Assignments

You can also delete multiple procedures for a location at once, and deleted multiple procedures for multiple equipment items at once.

- Load the Assign Procedures to Equipment or Location task, set a filter, and in the left pane you can toggle between a list of equipment, equipment systems, and locations in your facility.

- Select the locations, equipment, or items of an equipment system. In the In the top right frame, "Assigned Procedures Common to All Equipment/Locations", the system lists the procedures that are assigned to all selected items.

- Select one or more procedures from the top window and click Delete Selected. If you wish, you can first review each procedure's details using the Details button.

- The system will remove these assignments and display these procedures in the Available Procedures frame.

Associating Procedures with Equipment Standards

You may wish to associate procedures with equipment standards. To do this, filter on Equipment Standard, use Select All to select all records, and then make your procedure assignment. This is a convenient way to make “bulk assignments."

Note that the system acts on only records in the list, and not all records of the equipment standard. For example, if there are 250 pieces of equipment of a particular equipment standard and the display limit is 200, then the system will assign this procedure to only the 200 pieces of equipment displayed in the list. To assign the procedure to the other equipment of this equipment standard, you need to set a different filter that shows the remaining equipment.

Next

With the general procedure assigned to equipment and locations, you can now set the schedule for executing these procedures on the individual items.