Getting Results with Archibus

Commissioning

Acutely mindful of both the benefits and the risks, commissioning agents endeavor to deliver a superior commissioning process for their organizations. However, they are stymied by the lack of efficient electronic communication between design, construction and commissioning. The Revit design models are separate from the Navisworks construction information. Shop drawings are never uploaded. COBIE spreadsheets require manual steps to produce and must be manually exported after each and every change to any piece of information. The commissioning process becomes effort intensive and error prone.

The Archibus Commissioning application solves these problems. The application captures and coordinates building data -- including as-builts, shop drawings, maintenance manuals, space, and equipment information -- all in one central repository stored in a structured format. The application makes every piece of the data searchable and accessible over the Web.

Moreover, the application correlates the data in a format appropriate for lifecycle management. Spaces in the design BIM model become searchable records in the database that you can use for inventory, allocation, and occupancy. Similarly, equipment in the BIM model becomes records that contractors can link to equipment standards, O&M manuals, and preventive-maintenance procedures and steps. Archibus enterprise graphics let you view your BIM models instantly accessible over the Web -- without your having to install Revit or Navisworks or any other specialized design applications.

|

Commissioning |

|

|---|---|

|

Location |

Archibus non-SaaS

Archibus SaaS

|

|

Business Result |

Lower operational costs and reduce liabilities. Speed building occupancy. Use commissioning data to benchmark against on-going preventive maintenance procedures and periodic field testing over the complete lifecycle of your facility assets. This trending data enables you to identify and fix anomalies quickly, thus minimizing costs, operational downtime, and legal risks. Eliminate costly post-construction callbacks by providing an automated design review process. Increased productivity, comfort, safety, and health for building occupants due to enhanced building efficiency and environmental and health conditions. |

|

Used By |

Building Owners and Building Managers Architects and Engineers Commissioning Providers Project Managers Operations and Maintenance Staff |

|

Reasons for Automating |

To obtain early feedback. Archibus's live Web Services connect data transparently to give commissioning agents early visibility into the building-information model (BIM)-- even in the design-development stage when changes can be made inexpensively. To eliminate errors. Archibus enforces validation according to your BIM Execution Plan -- data entry errors don't need to be corrected, as they never occur. To accurately capture operational data. Archibus coordinates shop drawings, maintenance manuals, and preventive maintenance procedures -- right over the Web, directly from the subcontractors. To flag missing submissions. Dashboards color-code hundreds of documentation submissions so you can tell at a glance which are still missing or not yet approved. To speed field verification. With automatically-generated field-verification checklists, your field-service personnel simply verify -- rather than re-enter -- the correct information and meter readings. To speed occupancy. Having your documentation, space inventory, and maintenance data and processes in structured electronic form let you begin managing the building with this information on day 1. |

|

Results/Reports |

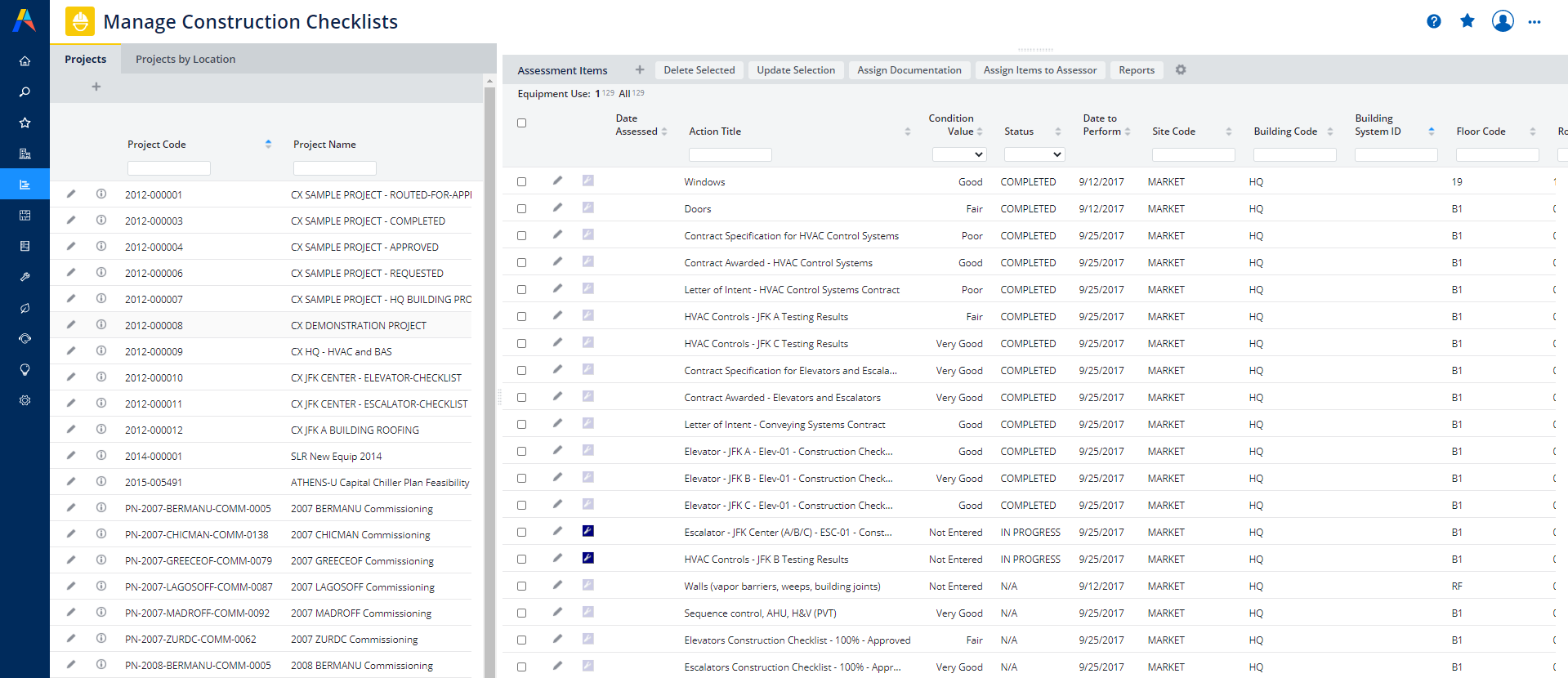

Manage Active Projects Owner's Project Requirements Contracts Awarded to Commissioning Agents Design Submissions Approved Commissioning Specifications The Commissioning Console Manage Construction Checklists Commissioning Project Scorecard Equipment Assessments by Classification Level Highlight Locations with Commissioning Issues Commissioning Project Close-Out Equipment Standards Book Equipment Plan Equipment Information Equipment by Department/Floor Equipment by Warranties Equipment by Insurers Equipment by Insurance Policies |

The following are typical users:

| User | Tasks |

|---|---|

| Building Owner and Building Managers |

Effective hand off of building equipment and systems reduce their cost of operation and extend their useful life. Verification that the building has been completed as designed lowers construction risk. Verification documentation that HVAC and safety systems work to spec reduces liability. Ability to use hand-off information to manage building on day 1 ensures that move in and operational activities proceed without wasted time or confusion. |

|

Architect and Engineers (A/E) |

Early visibility to the commissioning agents lets architects process their feedback early on, when changes are relatively inexpensive. Bringing the operations perspective to tasks such as equipment specification, space programming, and wayfinding-style room numbering detects changes that would be costly after construction. |

|

Commissioning Provider |

Templates divide commissioning data into verifiable lists of documents, and the commissioning process into discrete tasks that you can assign and verify. Consoles give green/yellow/red color-coded status of tasks so you know at a glance which are complete and which are at risk. Automatic actions use templates made by your commissioning domain-experts to create site-specific checklists for field personnel. |

| Project Manager |

Structured steps communicate your management protocols. Individual checklist items reflect each "turn over" commissioning records and track its status automatically. "One click" approval and rejection actions speed processing of submittals. Project management tools help you estimate and schedule workload for all commissioning projects in the pipeline. |

| Operations and Maintenance Staff |

Electronic hand off of equipment information and preventive maintenance procedures and steps lower effort required to onboard equipment and train staff. Accurate information and complete asset inventory reduce field-survey time and increase effectiveness of your maintenance program. Benchmarking design vs. actual performance and remaining equipment lifetime informs repair/replace decisions and future system selection. |